Robotics Solutions Guide

As technology innovation grows exponentially and moves beyond traditional manufacturing industries, especially automotive and electronics, the need for more reliable, flexible, and fast automation systems increases.

Significant installed base growth has led to a boom in new demand for industrial robots.

Collaborative Robotics

Until recently, human operators have been separated from large industrial robots due to safety concerns.

Industrial robots are often working in caged work cells. Collaborative robots have the ability to work safely, side by side with humans in small work cells. These small, flexible robots are ideal for small to medium manufacturing businesses where traditional robotics costs were too high.

Collaborative robots are increasingly programmed by "hands-on learning," where the user-operator physically moves the robotic arm through the desired task. The robot records the movement and can share its program with additional robots.

Companies are finding innovative ways to integrate them into their manufacturing processes, letting robots take over dull, repetitive tasks and allowing human operators to focus on higher-value work. These robots are often much smaller, semi-mobile, and easier to re-task. However, their design presents challenges in routing high-speed control networks through their many moving joints.

Robot Control

Robotic applications require very precise motion control. Each joint is managed by a servo mechanism using optical encoders, force feedback, and collision detection. Each robot typically has its own dedicated industrial PC controller.

Traditionally, robots worked independently, but there is growing emphasis on coordinating multiple robots within the same work cell.

Industrial Robot Communication Infrastructure

Communication protocols in robotics use standard industrial Fieldbus technologies: Ethernet/IP, EtherCAT, DeviceNet, PROFINET, Modbus-TCP, and CANOpen.

Older serial-based protocols are low-bandwidth, while modern Ethernet-based protocols offer high speeds but introduce wiring design challenges in robot arms and joints.

Cabling

Industrial robots are highly dynamic, moving through millions of cycles. Control buses are routed through moving joints, exposing cables to mechanical stress and electrical noise.

High-flex shielded CAT5 cables can be used for Ethernet applications, but they are expensive and limited to a few million torsion cycles. Plastic Optical Fiber (POF) offers a more durable, flexible solution.

Plastic Optical Fiber (POF) for Robotic Applications

- Proven durability with >25 million torsional cycles

- EMI/RFI immunity – ideal for noisy environments

- Supports Gigabit data rates

- Small cable diameter for routing through tight spaces

Firecomms Solutions

Firecomms offers transceiver devices for robotic and cobotic applications, supporting both low-speed command/control protocols and high-speed data rates up to Gigabit.

RedLink®, SMI and OptoLock® families provide reliable, EMI-hardened, field-terminable solutions designed for harsh industrial environments.

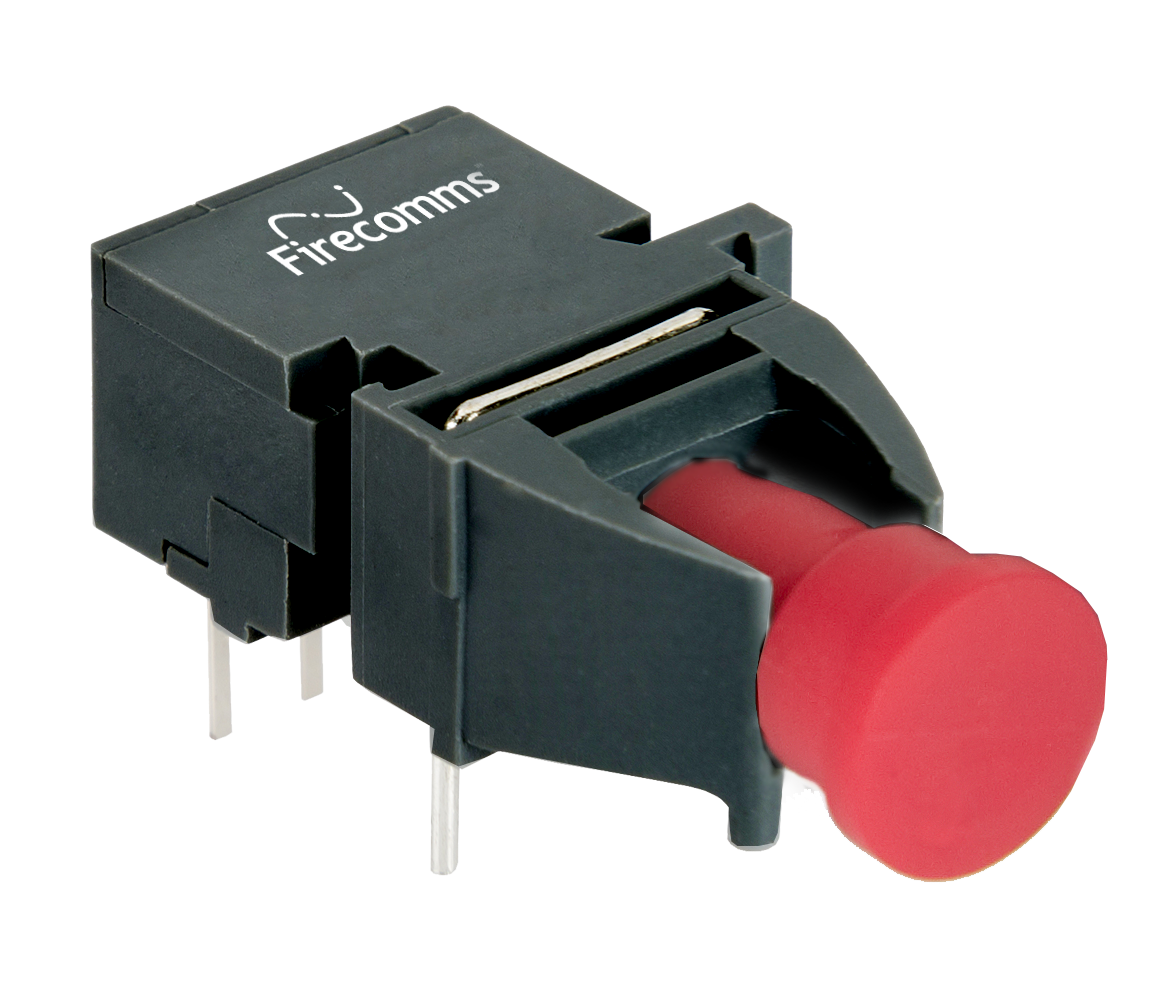

RedLink®

The form factor of the RedLink® (RL) family is compatible with the Versatile Link range of connectors and cables. We offer a range of industrial grade fiber optic transmitters and receivers (DC-1/5/10/50 MBd) in the RedLink® connector.

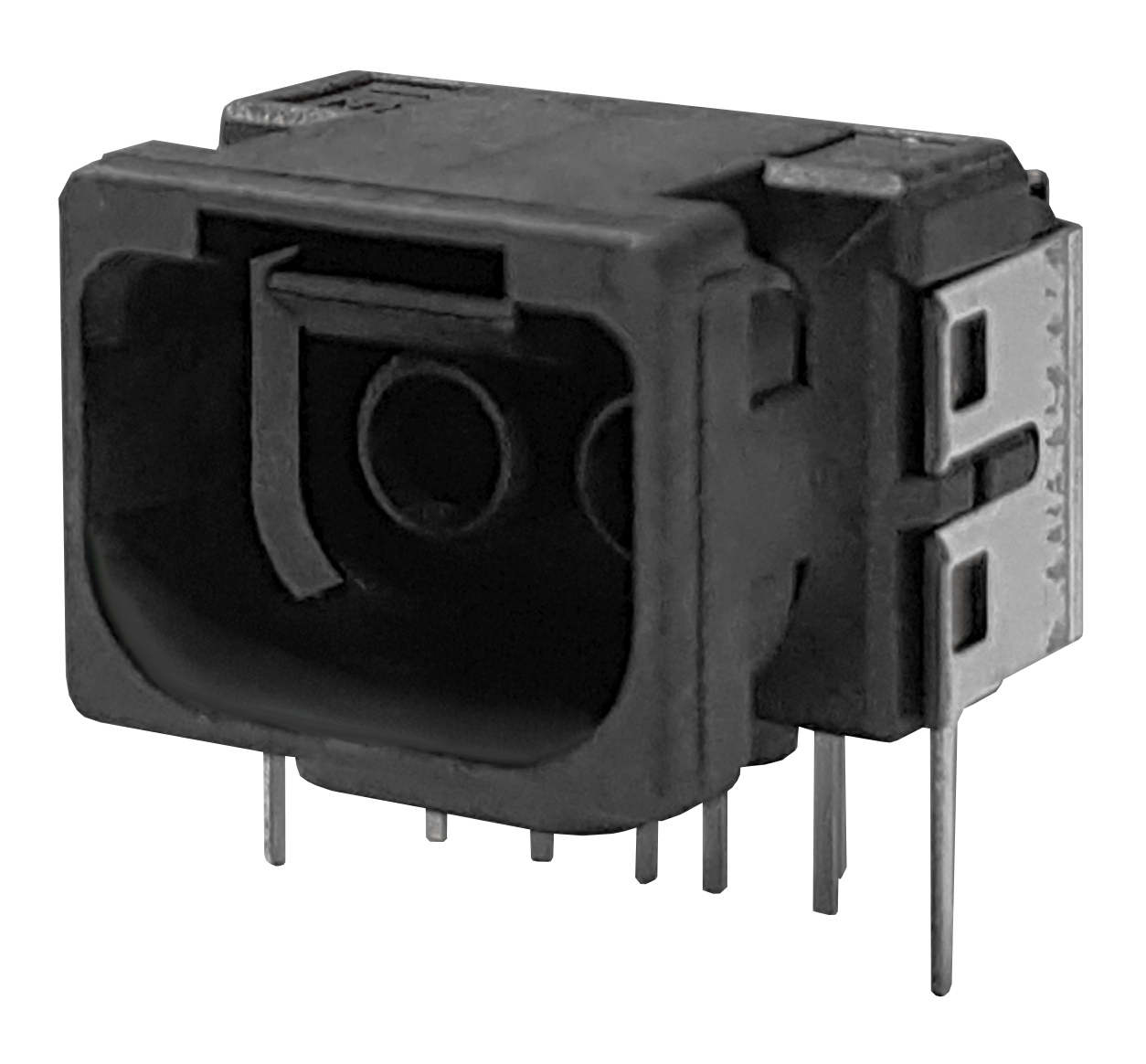

SMI Transceivers

Firecomms’ SMI transceivers comply to the IEEE1394b standard developed for communication over plastic optic fiber. Non-magnetic versions are available for Medical device applications.

OptoLock® Transceivers

The patented OptoLock® (OL) provides the quickest of terminations with bare POF at DC/5/10/125/250 Mbps and GigE speeds.

.png)

Full cable offering for your robotic application

Firecomms offers a range of high quality Plastic Optical Fiber cables. SMI, LC, and RedLink® plugs, and pre-assembled patch cords in all SMI, LC and RedLink® styles. These products are suitable for use with Firecomms’ range of transceivers and other industry-standard products.