Power System Management

Why use Plastic Optic Fiber (POF) around batteries?

Risks linked to Power Battery Management:

- Operating risk: When Battery systems are operational, they can generate significant EMI from the large changes of current over short time scales (large dI/dt), which can cause spikes on digital circuitry and damage micro controllers. The EMI can also cause drive systems to malfunction resulting in current surges producing heat damage, short circuits and also causing fire damage with resulting equipment loss and possibly personal injury.

- Maintenance risk: During routine maintenance a short circuit generating a current surge can result in personal injury, fire and equipment damage.

Plastic Optic Fiber Advantages:

- Plastic Optic Fiber is 100% plastic and consequently does not conduct electricity and cannot therefore cause a short circuit.

- Plastic Optic Fiber is also 100% immune from electrical or magnetic pickup hence it will isolate command and control digital electronics from the power switching electronics' interference usually located in a UPS or EV charging station. Equally POF can provide high speed data connections between devices without the risk of carrying unwanted EMI/RF interference from one unit to another.

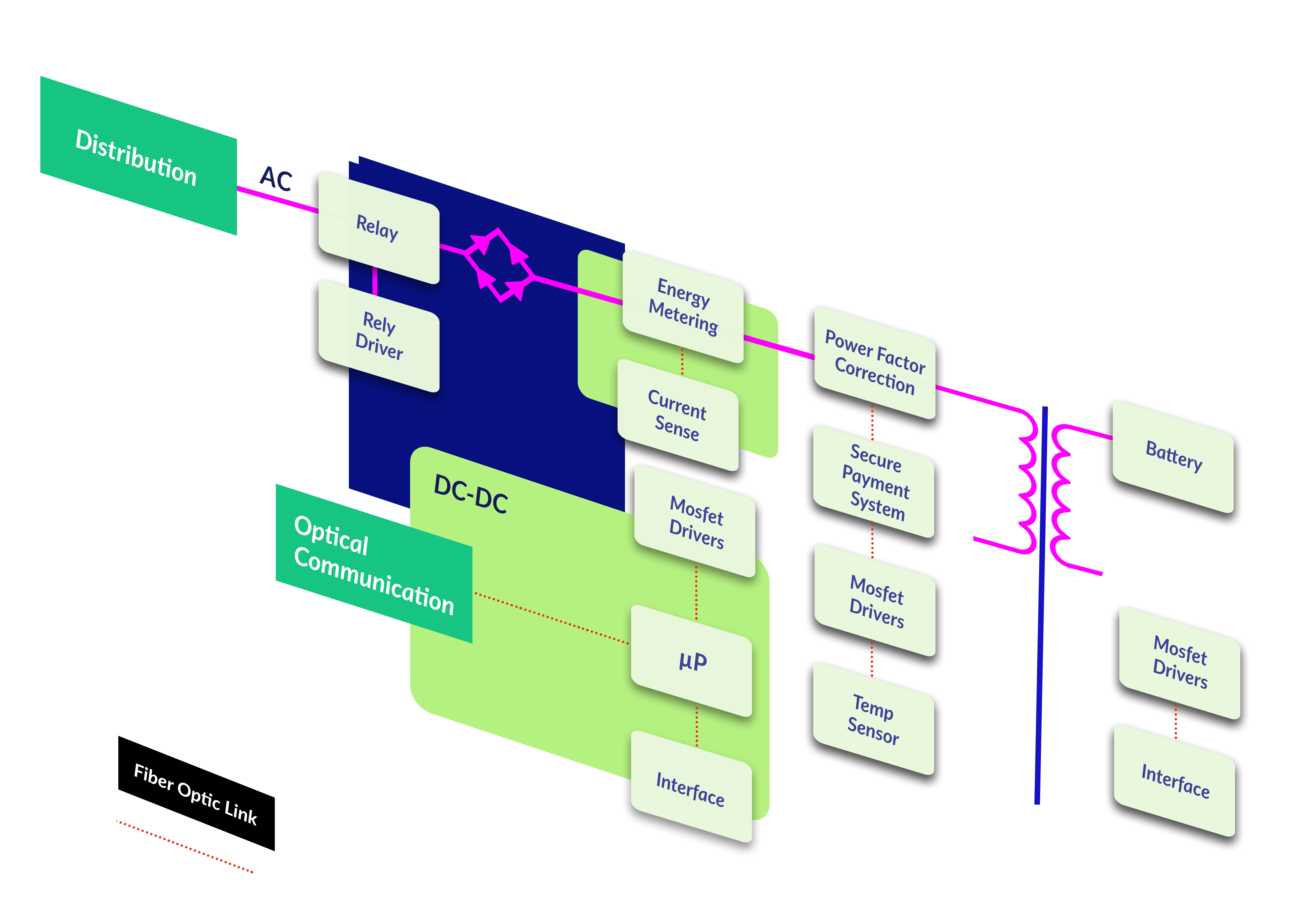

EV Charging Station

Benefits of Firecomms Fiber Optics for Power System Management Applications

Firecomms products with Plastic Optical or Plastic Clad Fiber (POF/PCS) links offer many advantages in power system management applications:

- EMI/RFI immunity ideal for harsh and noisy environments, such as high voltage rectifier control and HV DC inverters and power supplies

- Galvanic isolation between transmitter and receiver, ideal for complying with, or extending creepage and clearance distance requirements

- Visible spectrum operation enables eye-safe, fast troubleshooting

- Low power consumption, transmitters capable of operation at 3-4mA

- Durable, flexible and lightweight

- Resilient to bending and vibrations

- High reliability for extended machine uptime

- Industrial temperature in range of -40 to +85ºC

- Reduced maintenance cycle time provides up to a 20-year lifecycle on transceivers and cables

- Simplified field installation for easy termination of large core optical fibers in custom distances

Click below to find out more

Electrical Power Management Solutions Guide